How to Assess THC and CBD Levels in Cannabis Strains and Products

Share

The original article is USA based and comes from Leafy and is provided as is:

https://www.leafly.com/news/science-tech/how-to-assess-thc-cbd-levels-in-cannabis-strains-products

How to Assess THC and CBD Levels in Cannabis Strains and Products

How much THC does your favorite cannabis product contain? The answer may not be as straightforward as reading the “total THC” number that is (hopefully) printed on the label. There is no official industry standard for calculating the total THC of a cannabis product, and different producers and testing facilities calculate it in different ways. As a consumer, what you’re really after is the amount of THC or CBD that will be available for your consumption, which will depend on the content of the product, the route of administration, and the method of consumption.

Let’s take a closer look at the different ways you can estimate THC levels in cannabis products (the same logic applies to CBD).

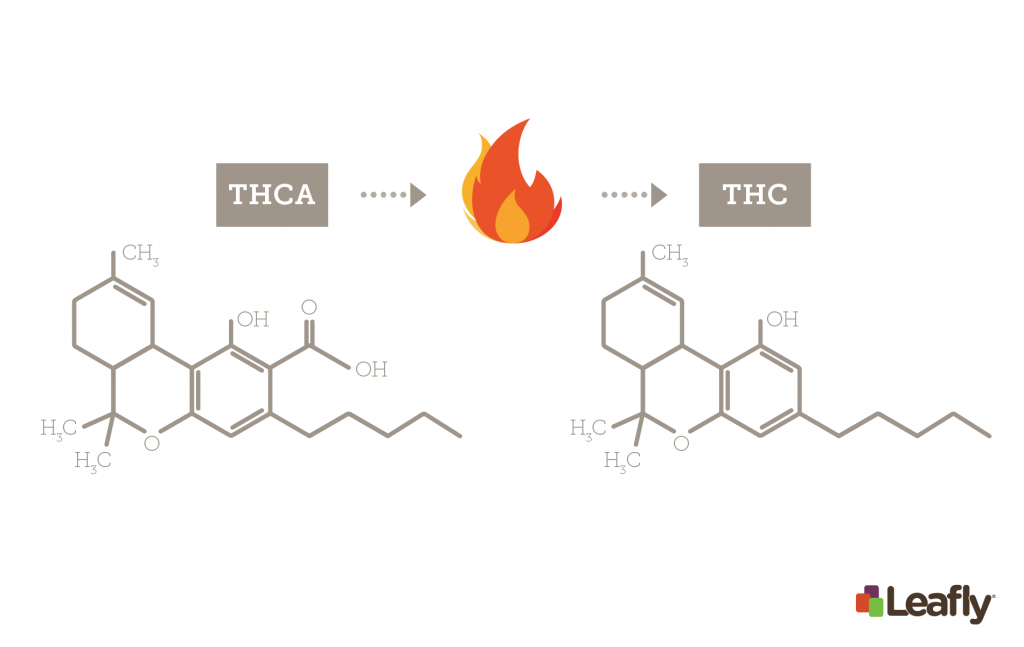

THCA, THC, and Decarboxylation

If you want to know how potent a cannabis product is, it helps to understand the difference between THCA and THC, and how one gets converted into the other. Cannabis does not make THC, it makes THCA, which is a non-intoxicating compound that can be converted into THC through decarboxylation. This typically occurs in the presence of heat energy applied by the consumer. When your lighter, vaporizer, or oven heats up your cannabis product, THCA gets converted into THC. Many people talk about “activated” vs. “inactive” THC. This is what they mean.

THCA, THC, and Reading Cannabis Product Labels

Most cannabis products sold legally in CANADA and the usa are required to be tested and labeled for THC and CBD content. However, when you examine a typical label, you’re likely to see several numbers, such as CBDA, CBD, THCA, and THC percentages, and perhaps things like “Total THC” and “Total Cannabinoids.” Let’s look at a real-life example from Washington state:

Let’s focus on three numbers under the “Potency Analysis” of the above label: THC, THCA, and total THC. On this label, the THC level is 1.0%. Most labels will display a low number like this because the plant contains mostly THCA, which needs to be decarboxylated (“activated”) by heat. In this case, we see 23.2% for the THCA level.

Things get tricky when we look at the “total THC” level, which is 21.35% here. Total THC is supposed to refer to how much THC will be present as a percentage of dry weight after the THCA has been converted into THC. On this example label, “total THC” is 21.35%. But wait, if we have 1.0% THC and 23.2% THCA, why isn’t total THC 24.2%? Shouldn’t we just add the THC and THCA percentage levels together, since THCA will get converted into THC? Nope. There are a couple things that make this tricky.

First, THC isn’t quite as heavy as THCA, so we need to account for that. This makes sense if you look at the chemical structures for THCA vs. THC (Figure 1). THC is just THCA after a piece gets chopped off. So, THC is lighter—it’s 87.7% of the molecular weight of THCA. That’s why total THC on the above label is 21.35% instead of 24.1%. When you see something like “Total THC” on a product label, they should be getting that number using a calculation that takes this into account (see Method 2 in Figure 3 below).

Second, the process of turning THCA into THC is not 100% efficient—not every THCA molecule will be converted into a THC molecule, and at very high temperatures, some of the THC may degrade into CBN. Our friends at Steep Hill Labs estimate that 75% is a representative upper limit for what fraction of THCA will end up as THC. In that case, for every four molecules of THCA that get heated during consumption, only three get successfully converted to THC.

While this type of calculation provides a more accurate estimate of final THC levels, in practice it’s very difficult to know what your THCA to THC conversion efficiency will be; it will depend on how long your flower is exposed to heat, the exact heating temperature, and the device you’re using.

Final THC Levels Depend on Consumption Method

To better understand how different consumption methods affect decarboxylation rates and the final THC content in cannabis products, Leafly spoke with Rudolf Brenneisen, PhD. His lab at the University of Bern, in Switzerland, has extensively studied how decarboxylation rates and THC availability are influenced by different products (specifically, vaporizers) and routes of administration.

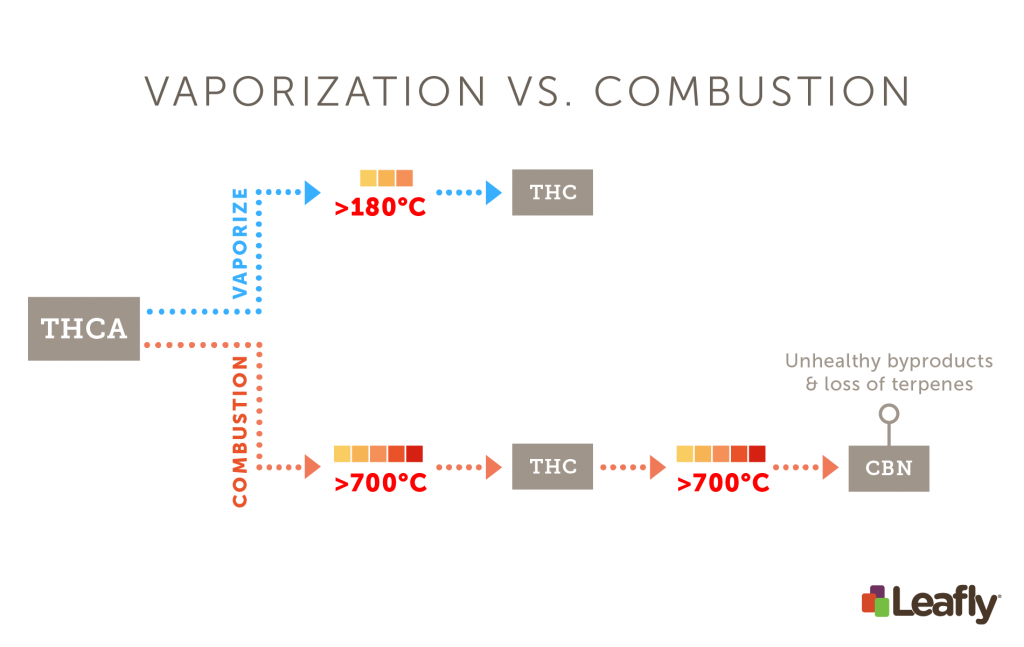

Dr. Brenneisen emphasized that “Decarboxylation efficiency/rate depends on heating temperature and time, as well as the vaporizer design and technology.” His lab has specifically studied how different vaporization temperatures and products affect how efficiently THCA is converted into THC in both flower and cannabis extracts. “Heating of cannabis extracts at 200°C for five minute results in almost 100% decarboxylation of THCA to THC, without forming CBN,” he said.

Decarboxylation of THCA to THC starts occurring at around 180°C. As you increase the temperature from there, other compounds like terpenes will begin to vaporize, each at a different temperature. At even higher temperatures, you’ll start to get combustion. This will affect not only levels of THC and other cannabinoids, but also terpenes. Moreover, combustion can produce byproducts that may be hazardous to your health.

“Burning of cannabis (not tested and validated in my lab) at >700°C will probably result in a higher decarboxylation rate, but also more degradation to CBN and the production of potentially harmful byproducts. In addition, temperatures that are too high lead to loss of terpenes, which are important ‘entourage effect’ compounds,” Dr. Brenneisen explained.

There isn’t an exact, magic number for the temperature at which cannabis flower starts to combust, but the temperature range of most commercial electric vaporizers should be below this threshold. Traditional smoking methods that directly ignite flower are a different story. The temperature of a typical Bic lighter flame will be well over 1,000°C, which would be expected to cause degradation of THC into CBN and some destruction of terpenes. These factors will naturally influence the nature of your experience.

The Takeaway

You want to know the theoretical maximum percent dry weight value for the THC content of your product. The same logic applies to CBD. If the product is labeled well, this value should appear as “total THC” or something similar, and should be calculated as follows:

Total Potential THC = (0.877 * %THCA) + %THC

This is the theoretical maximum amount of THC present in your product. It accounts for the weight difference between THCA and THC, and assumes 100% conversion of THCA into THC. But the conversion efficiency may not be 100%, which is why this is a maximum estimate. The real amount of THC available for your consumption will probably be lower than this number. Estimating exactly how much lower is tricky because, as we explored, it depends on the details of your consumption method. And of course, all of this depends on having a cannabis product that has been honestly and accurately measured. It’s entirely possible that certain cannabis products on the market today have not been accurately tested, and the numbers on the label may be inflated. If you’re new to cannabis, be sure to ask a budtender to recommend quality products from trusted sources.